Amar RapidCoat Tablet Coating System: A Premier Automatic Tablet Coater

Unmatched Precision and Efficiency

The Amar RapidCota Tablet Coating System is a state-of-the-art automatic tablet coater that revolutionizes tablet coating with unparalleled precision and efficiency, embodying over six decades of Amar Engineering Works’ innovation. Trusted in over 200 top-tier pharmaceutical facilities the Amar RapidCota sets the industry standard as a leading pharmaceutical tablet coater.

Streamlined Production with Superior Quality

Designed for maximum adaptability, the Amar RapidCota excels in reducing waste and enhancing operational efficiency. Its advanced features ensure consistent high-quality outputs, making it indispensable for modern pharmaceutical manufacturing. This tablet coater’s robust performance and environmental compliance make it the preferred choice for industry leaders seeking reliable and sustainable production solutions.

Advanced Features of Amar RapidCotA: Engineered for Excellence

Perforated Coating Pan:

Ensures uniform and damage-free tablet processing.

Advanced Nozzle Design:

Anti-bearding technology reduces maintenance, improves coating evenness.

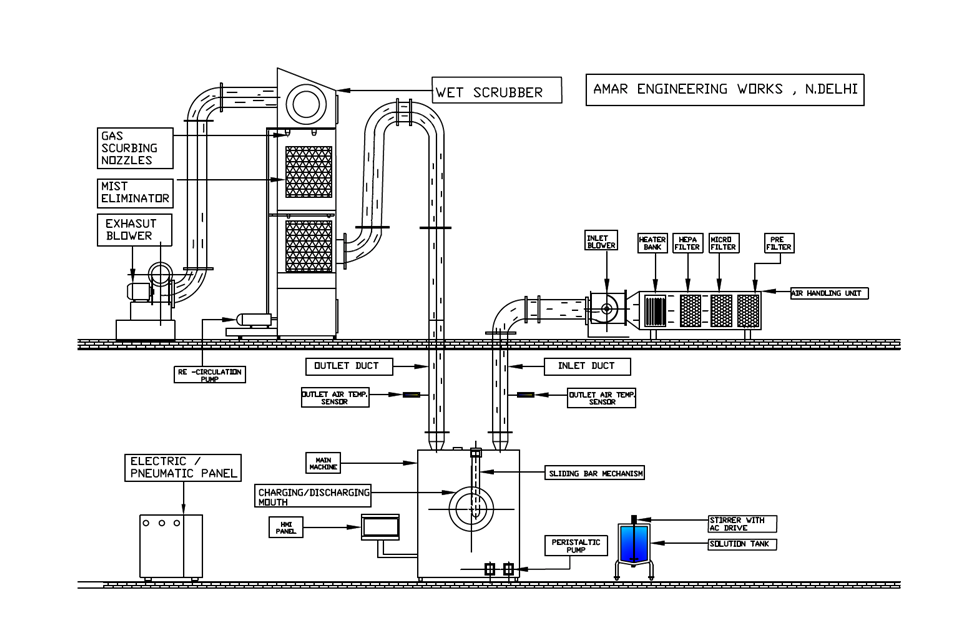

Superior Air Filtration:

Integrates PRE/MICRO and HEPA filters for optimal air quality.

Emission Control Technology:

Includes wet scrubber options for environmental compliance.

Precision Nozzle Alignment:

Ensures accurate coating applications.

High-Efficiency Dosing System:

Multi-head peristaltic pumps provide precise dosage control.

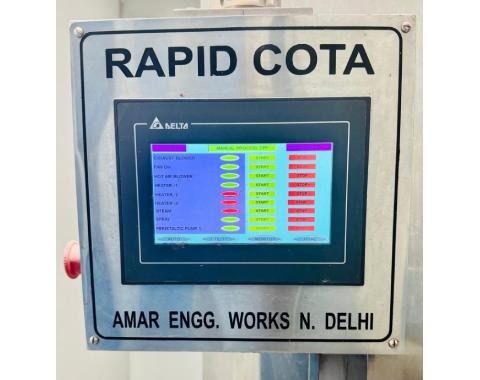

User-Friendly Interface:

Simplifies operations and minimizes training needs.

Effective Thermal Management:

Maintains optimal temperatures for heat-sensitive compounds.

Flexible Coating Options:

Handles various coating substances, from basic to complex polymers.

Scalable from Pilot to Production:

Designed for easy scale-up, ensuring seamless transitions.

Safety First: Dedicated Features to Protect Product and Personnel

Technical Specifications

| Specification | RapidCota 12 | RapidCota 24 | RapidCota 36 | RapidCota 48 | RapidCota 60 |

|---|---|---|---|---|---|

| Pan Diameter (mm) | 305 | 610 | 910 | 1220 | 1524 |

| Mouth Opening (mm) | 175 | 250 | 360 | 450 | 500 |

| Volume (L) | 1.4 | 20 | 70 | 200 | 400 |

| Optimal Batch (kg) | 3 | 15 | 50 | 150 | 250 |

| Motor (HP) | 0.5 | 1.5 | 5 | 7.5 | 7.5 |

| Pan (RPM) | 2 to 15 | 1 to 24 | 1 to 16 | 1 to 10 | 1 to 10 |

| Inlet Blower Motor (HP) | 1.5 | 3 | 3 | 5 | 5 |

| Airflow Inlet (CFM) | 825 | 1200 | 1500 | 2500 | 4500 |

| Exhaust Blower Motor (HP) | 3 | 5 | 5 | 10 | 10 |

| Airflow Outlet (CFM) | 900 | 1500 | 2000 | 3500 | 6000 |

| Steam Consumption (2–4 bar, Kg/Hr) | 10 Kg/hr | 25 Kg/hr | 50 Kg/hr | 100 Kg/hr | 150 Kg/hr |

| Water Consumption for Washing | 50 Lts | 75 Lts | 150 Lts | 150 Lts | 200 Lts |

| Spraying Nozzle | 1 | 2 | 3 | 4 | 4 |

genEral working